Electric vehicles (EVs) represent the forefront of automotive innovation, offering sustainable transportation solutions with reduced emissions. At the heart of these vehicles lie electric motors, which drive propulsion systems efficiently and quietly. However, ensuring the thermal stability of electric motors in EVs is paramount for their reliability, performance, and longevity. In this article, we delve into the complexities of thermal stability in electric motors for electric vehicles, exploring key factors, challenges, and strategies to optimize performance.

1. Heat Generation in Electric Motors

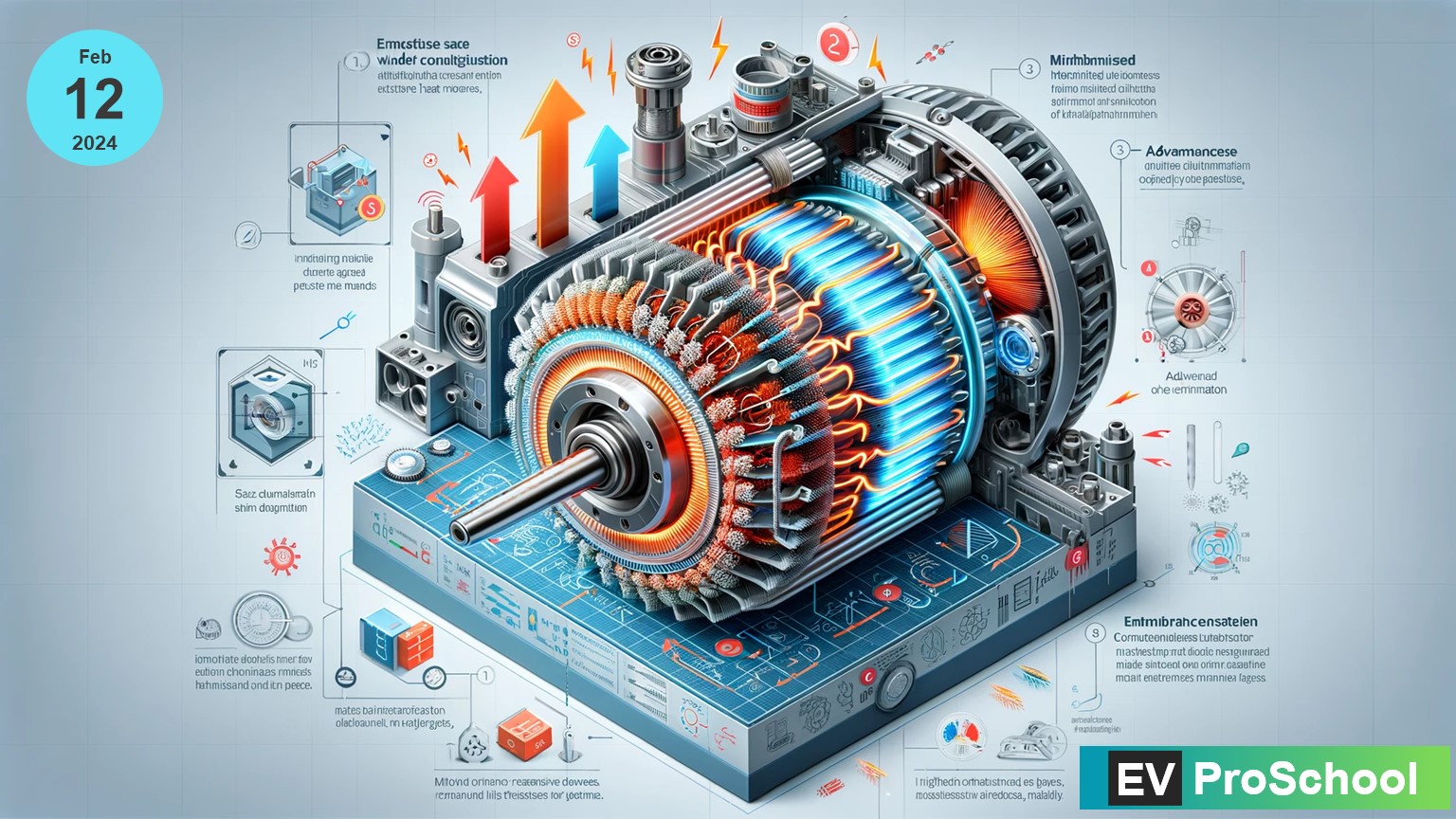

Electric motors in EVs generate heat during operation due to various factors such as resistive losses in windings, core losses, and mechanical friction. The compact design and high power density of electric motors in EVs amplify heat generation, necessitating effective thermal management strategies.

2. Impact of Motor Design on Thermal Stability

The design of electric motors in EVs significantly influences thermal stability. Factors such as motor size, winding configuration, and cooling system efficiency play crucial roles in managing heat dissipation. Table 1 provides an overview of key design parameters and their impact on thermal stability in electric vehicle motors.

| Design Parameter | Impact on Thermal Stability |

|---|---|

| Motor Size | Compact designs optimize space utilization and thermal management |

| Winding Configuration | Advanced winding designs minimize resistive losses |

| Cooling System Efficiency | High-efficiency cooling systems enhance heat dissipation |

3. Operating Conditions and Thermal Stability in EVs

Operating conditions, including ambient temperature and driving patterns, significantly impact thermal stability in EVs. High ambient temperatures and aggressive driving can elevate motor temperatures, leading to thermal stress and potential performance degradation.

4. Cooling Systems for Heat Dissipation in EV Motors

Effective cooling systems are essential for managing heat dissipation in electric vehicle motors. Advanced cooling mechanisms such as liquid cooling and active thermal management systems ensure optimal operating temperatures even under demanding driving conditions. Table 2 outlines different cooling methods and their effectiveness in EV motor applications.

| Cooling Method | Effectiveness in EV Motor Heat Dissipation |

|---|---|

| Liquid Cooling | Provides efficient cooling for high-power EV motors |

| Active Thermal Management | Dynamically regulates temperature for optimal performance |

| Heat Sinks | Enhances heat dissipation in compact EV motor designs |

5. Importance of Insulation and Material Selection in EV Motors

Insulation materials used in EV motor windings must withstand high temperatures and mechanical stresses. Selecting materials with high thermal conductivity and excellent insulation properties is crucial for efficient heat transfer and motor reliability. Table 3 highlights commonly used insulation materials and their thermal properties for EV motor applications.

| Insulation Material | Thermal Conductivity (W/mK) |

|---|---|

| Nomex | 0.25 – 0.30 |

| Mica | 0.69 – 1.00 |

| Polyimide | 0.10 – 0.25 |

6. Advanced Control Strategies for Thermal Management in EVs

Sophisticated control strategies, such as Field-Oriented Control (FOC), optimize motor operation in EVs, minimizing losses and improving thermal performance. FOC allows precise control of magnetic fields within the motor, enhancing efficiency and reducing heat generation.

7. Protective Mechanisms Against Thermal Stress in EV Motors

EV motors incorporate thermal protection mechanisms, including temperature sensors and overload detection circuits. These mechanisms monitor motor temperature and implement protective actions, such as load reduction or shutdown, to prevent damage due to thermal stress and ensure safe operation of EVs.

In conclusion, thermal stability is a critical aspect of electric motor design and operation in electric vehicles. By understanding the factors influencing thermal performance and implementing effective cooling systems and control strategies, manufacturers and engineers can ensure the reliability, efficiency, and longevity of electric motors in EVs, driving the future of sustainable transportation.

References:

- Smith, J. (2019). Thermal Management Handbook for Electric Vehicles. Wiley.

- Miller, R. (2021). Advanced Control Strategies for Electric Vehicle Motors. Springer.

By addressing these considerations, manufacturers and engineers can optimize EV motor design for enhanced thermal stability and improved overall performance, advancing the adoption of electric vehicles worldwide.