Have you noticed more electric scooters and cars on the road lately? With terms like EV, mild hybrid, strong hybrid, buyback, fast charging, and slow charging everywhere, it’s easy to feel confused. How are they shaping the future of green mobility and the joy of riding?

In this post, let’s break down the different types of EVs and the basic components that power these vehicles. By the end, you’ll clearly understand how EVs work and be ready to join discussions with colleagues and friends, sounding like a cool expert!

1. Types of Electric Vehicles (EVs)

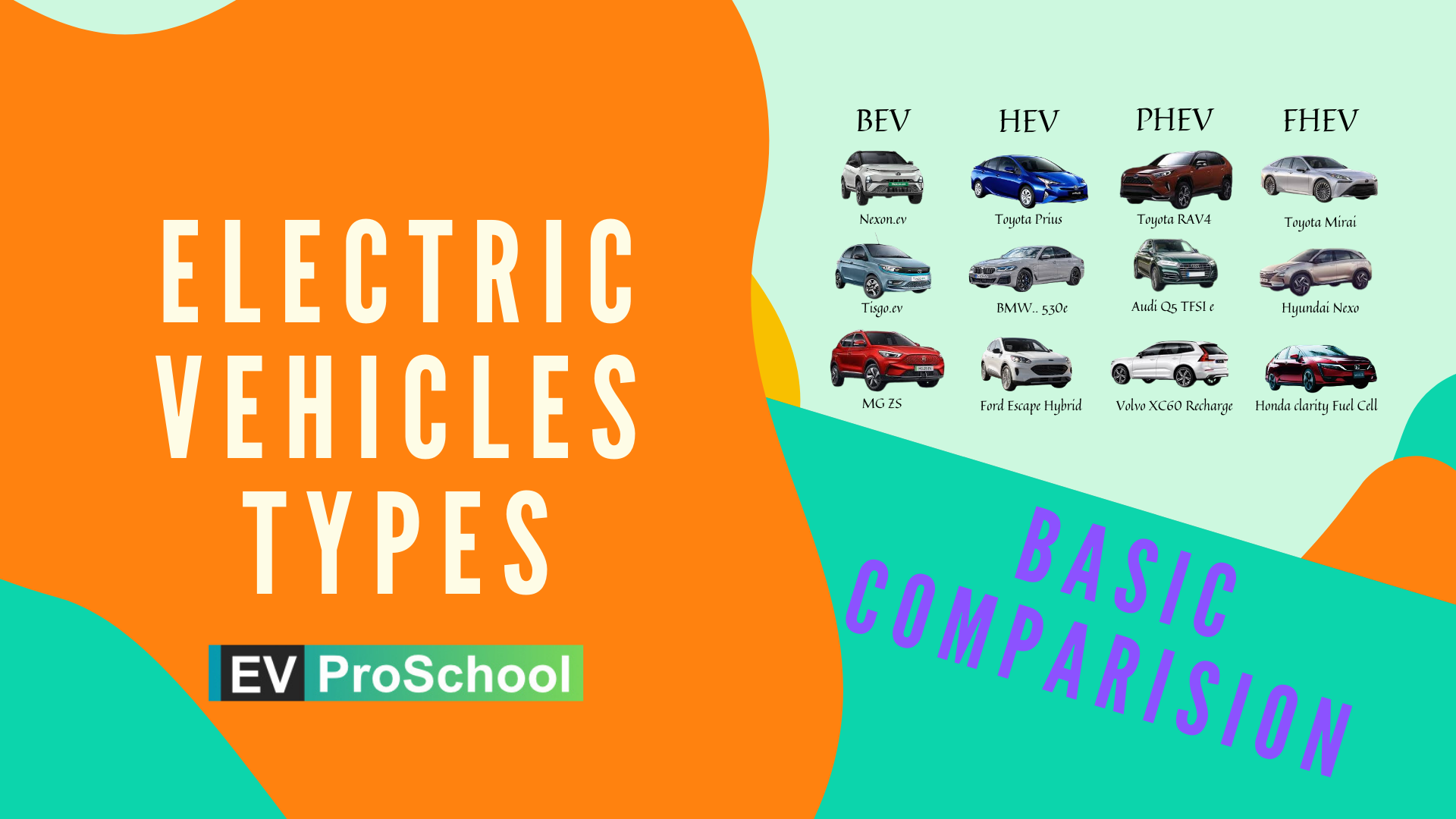

There are four main types of electric vehicles, categorized by their power sources:

Battery Electric Vehicles (BEVs): Powered entirely by batteries, which supply electricity to the motor to drive the vehicle. They are 100% battery-powered and zero-emission.

Plug-in Hybrid Electric Vehicles (PHEVs): Equipped with a battery large enough to drive the vehicle, along with an internal combustion engine. The battery can be charged externally, and the engine is used as a backup.

Hybrid Electric Vehicles (HEVs): Have a small battery (about one-tenth the size of the engine capacity) that assists the engine for starting, low-speed driving (under 20 km/h), and regenerative braking. The primary power comes from the engine, and the battery cannot be charged externally. An example is the Toyota Prius.

Fuel Cell Electric Vehicles (FCEVs): Run on hydrogen fuel cells, which generate electricity to power the motor. Like BEVs, they are zero-emission vehicles.

While BEVs and FCEVs produce no emissions, PHEVs and HEVs reduce pollution compared to traditional internal combustion engines.

Comparison of Types of Electric Vehicles (EVs)

| Parameter | Battery Electric Vehicles (BEVs) | Plug-in Hybrid Electric Vehicles (PHEVs) | Hybrid Electric Vehicles (HEVs) | Fuel Cell Electric Vehicles (FCEVs) |

|---|---|---|---|---|

| Energy Source | – Fully electric, powered by batteries | – Batteries + internal combustion engine (ICE) | – Primarily ICE with battery assistance | – Hydrogen fuel cells generate electricity |

| Fuel Type | – Electricity only | – Electricity + gasoline/diesel | – Gasoline/diesel | – Hydrogen |

| Charging | – Requires external charging via charging stations | – Requires external charging + refueling gasoline | – Does not require external charging | – Requires hydrogen refueling |

| Emissions | – Zero tailpipe emissions | – Low emissions (in electric mode) | – Reduced emissions compared to conventional vehicles | – Zero tailpipe emissions |

| Range | – Typically 250–500 km per charge | – 40–80 km electric range + extended range via ICE | – Limited electric range, mostly relies on ICE | – Typically 300–400 km per hydrogen tank |

| Maintenance | – Low maintenance (fewer moving parts) | – Moderate maintenance (complex systems) | – Moderate maintenance (dual systems) | – Moderate to high maintenance (hydrogen systems) |

| Cost | – Higher initial cost, lower operating cost | – Moderate cost, depends on usage | – Lower upfront cost, higher operating cost | – High upfront cost, limited hydrogen availability |

| Key Advantage | – 100% electric and environmentally friendly | – Versatile, can run on both electricity and fuel | – No charging required, familiar fuel system | – Fast refueling and zero emissions |

| Key Limitation | – Limited charging infrastructure in some areas | – Short electric range, depends on ICE for longer trips | – Relies on ICE, less efficient compared to BEVs | – Expensive hydrogen infrastructure |

| Examples | – Tesla Model 3, Tata Nexon EV, Hyundai Kona EV | – Toyota Prius Prime, Volvo XC90 Recharge | – Toyota Camry Hybrid, Honda City e:HEV | – Toyota Mirai, Hyundai Nexo |

2. Focus on Battery Electric Vehicles (BEVs)

BEVs have fewer moving parts compared to PHEVs, HEVs, and FCEVs, leading to: Lower maintenance costs, higher reliability, and Less downtime for repairs.

BEVs have Zero Tailpipe Emissions, are fully electric no Engine, save are higher on fuel cost, global Carbon neutrality targets.

3. Basic Components of an Battery Electric Vehicle

A. Battery Pack

Role: Stores electricity as the primary energy source for the vehicle.

Key Details: Commonly Lithium-ion technology is being used. Battery Capacity is measured in Kilo Watt. Currently, battery energy density is low compared to Hydrocarbob-based fuel, hence battery weight increases. Out of various commercial technology available Lithium-ion (Li-ion) batteries have one of the highest energy densities.

Discover More : EV Battery Lifecycle: Innovations from Chemistry to Reuse

Challenges:

- The high cost of Li-ion batteries makes EV ownership expensive initially, though it offers long-term savings.

- The buyback and resale value of EVs largely depend on the battery, but the market is still niche and lacks clarity.

- Battery repairs require specialized expertise, leading to high repair costs and warranty complications.

- These issues often result in customer dissatisfaction and hesitation to purchase EVs.

- Safety concerns, including fire incidents, further discourage potential buyers from adopting EVs.

- EV batteries are placed at the bottom of the vehicle, prone to damage on Indian roads. Pebbles or sharp edges can harm the battery unnoticed by the customer. Damage may surface 3–6 months later and is usually not covered by insurance.

The below table represents the various battery capacity for the various type of EVs.

| Type of Electric Vehicle | Typical Battery Capacity | Reference Notes |

|---|---|---|

| Battery Electric Vehicles | 18 kWh to 60 kWh | Indian Model Study |

| Plug-in Hybrid | 8 kWh to 34 kWh | evstatistics |

| Hybrid Electric Vehicles | 0.65 kWh to 2 kWh | lifewire |

| Fuel Cell Electric Vehicles | 1.6 kWh to 13.6 kWh | wikipedia |

B. Electric Motor (E-Motor)

Role: Converts electrical energy from the battery into mechanical energy to drive the wheels.

Key Details:

- Types of Motors and Applications: Induction Motors (IM) and Permanent Magnet Synchronous Motors (PMSM) are commonly used in electric vehicles. Low-voltage motors (below 60V) are used in light EVs (2W & 3W), while high-voltage motors are used in passenger vehicles and above applications.

- Role of Permanent Magnets: Most EV motors use permanent magnets in their cores to create a magnetic field. These magnets require high magnetic strength and intensity to reduce motor size and ensure optimal performance and torque.

- Manufacturing Requirements: EV motors demand stringent manufacturing processes, including potting, flexible laminates, and varnishes, to ensure insulation and durability.

Discover More : Unlocking the Power of Electric Vehicle IPM Synchronous Motors

Keep Exploring : Axial vs. Radial Flux Motors: The EV Technology Revolution

Challenges:

- Dependency on Rare Earth Magnets: Motors use rare earth magnets, increasing dependency on China, especially for countries like India with limited reserves. This raises costs, increases dependency, and gives China an advantage for its local EV brands, influencing global geopolitics.

- Complexity of EV Motors: EV motors are highly dynamic, requiring instant responses to driver demands. Their control strategies involve complex software and hardware, posing challenges for countries like India, which is still developing advanced motor capabilities. This creates a need for rapid skill development to meet the demand for expertise and job creation.

- Market Trends and Innovations: India is witnessing joint ventures for motor development. New-age axial flux motors are entering the market, offering superior performance and an edge to EVs, further driving innovation in the industry.

The below Table sheds light on the motor Power range as per the vehicle Category.

| Vehicle Category | Motor Power Range | Market Size Insights |

|---|---|---|

| Two-Wheelers (2W) | 0.4 kW to 25 kW | – Global market: USD 70 billion growth |

| Three-Wheelers (3W) | 2 kW to 8 kW | – Last-mile connectivity and public transport, |

| Four-Wheelers (4W) – Passenger Vehicles | 20 kW to 200 kW | – growth depends on charging infra |

| Commercial Vehicles | 150 kW to 240 kW | – Strong growth in fleet electrification |

| Buses and Trucks | 150 kW to 400 kW | – Transition to meet emission reduction targets. |

C. Controller

Role: Manages the flow of electricity from the battery to the motor.

Key Details:

- Brain of Vehicle: Controllers manage various functions based on the vehicle category, application, load, and processes.

- Programming and Behavior: Controllers are programmed with specific codes to instruct components on what to do and how to do it, while engineers define the “why” in the memory. The behavior of an EV depends on its processing power and how carefully it has been programmed and designed.

- Types and Communication: EVs have multiple controllers like battery management controllers, motor controllers, and thermal management controllers. These communicate with each other via standard communication protocols, such as CAN and LIN, through various channels.

Read More : Control Strategies Behind Electric Light Electric Vehicles in India

Explore More: Advanced Motor Control: PMSM and Induction Motors

Challenges:

- Complexity of Motor Controllers: Motor controllers are a complex technology requiring significant expertise. With advancements in electronics, controllers are becoming smaller and smarter, but there remains ample scope for improvement and a vast market potential.

- EVs as Computers on Wheels: With the rise of ADAS (Advanced Driver Assistance Systems) and electric vehicles, EVs have evolved into “computers on wheels,” demanding highly dynamic, safe, and stringent regulatory and standardization measures.

Below table summarizing key manufacturers of EV controllers and their countries of origin:

| Manufacturer | Country of Origin |

|---|---|

| Bosch | Germany |

| Continental AG | Germany |

| Denso Corporation | Japan |

| Mitsubishi Electric | Japan |

| Delphi Technologies | United Kingdom |

| Nidec Corporation | Japan |

| Siemens AG | Germany |

| Tata Elxsi | India |

| KPIT Technologies | India |

| Revoh Innovations | India |

| GTAKE | China |

| BYD | China |

| Infineon Technologies | Germany |

| Texas Instruments | United States |

| STMicroelectronics | Switzerland/France |

Conclusion

- Keypoints

- 4 Types of EVs, BEV leading the Race with 60% of ZEV market share.

- Cost of major 3 Compoenents, Battery (40%), Motor & Controller (25%)

- BEV sells growing at CAGR of 50%, creating more opportunity and shift in Job market.

- Call to Action:

- “The shift to electric mobility is more than a trend; it’s a necessity. Are you ready to join the movement?”

- Subscribe to Our Channel and let us know your comments and questions.