Electric motors are the heartbeat of the electric vehicle (EV) industry, propelling everything from compact cars to massive buses with efficiency and precision. However, like any critical component, they are susceptible to various forms of stress that can diminish their performance, shorten their lifespan, or even lead to catastrophic failure.

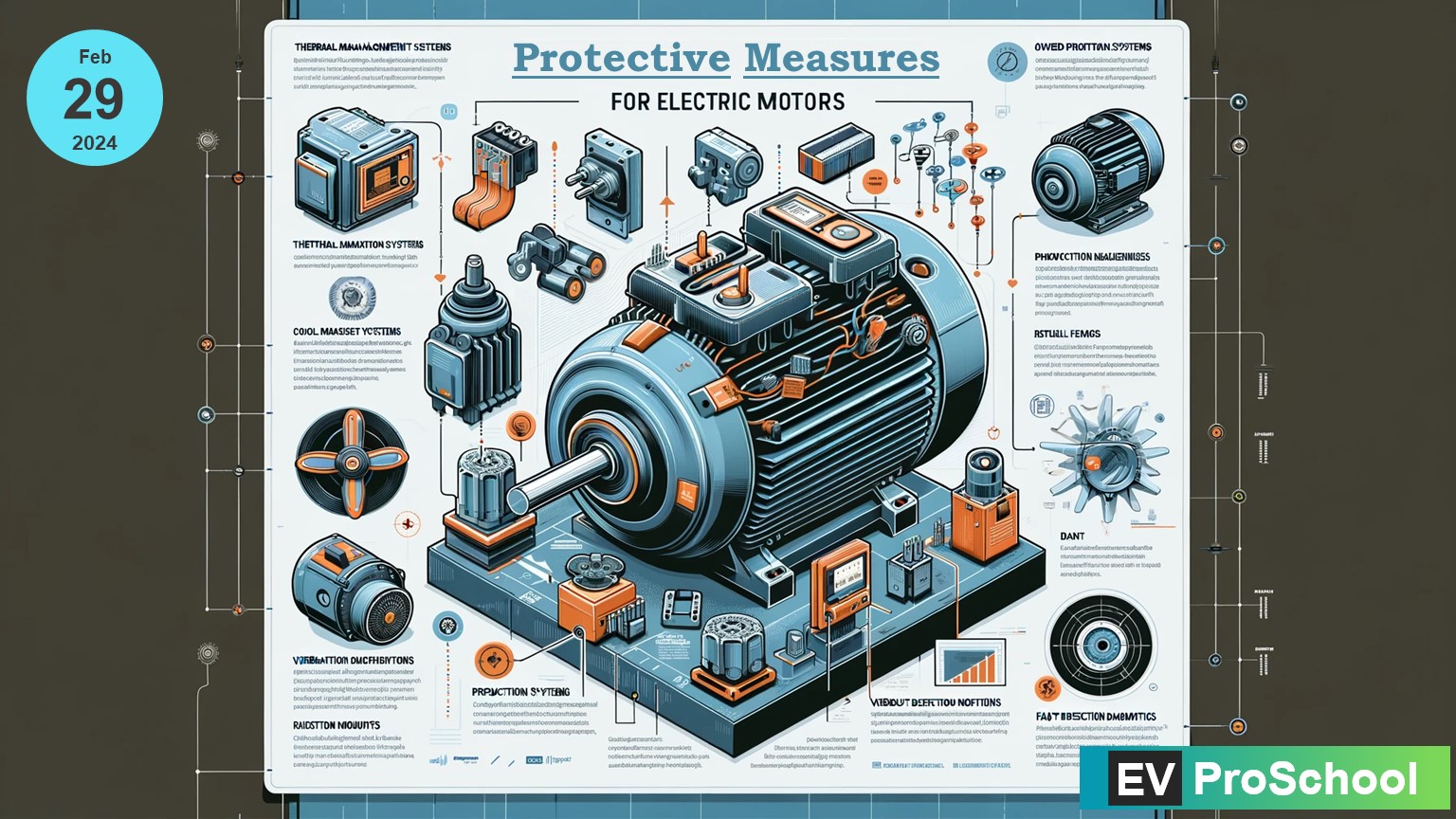

This blog delves into the essential protective measures for electric motors, focusing on thermal management systems, overload protection, vibration damping mechanisms, and fault detection and diagnostics. Understanding and implementing these strategies are crucial for maximizing motor durability and reliability, especially in the demanding conditions faced by electric vehicles.

1. Thermal Management Systems: Keeping Electric Motors Cool

Electric motors are equipped with sophisticated thermal management systems to regulate temperature and prevent overheating. Excessive heat can lead to material degradation, reduced efficiency, and premature failure. By employing advanced cooling techniques, such as liquid cooling systems or air-flow management, we can significantly extend the life of electric motors and enhance their performance

| Measure | Description | Example |

|---|---|---|

| Liquid Cooling Systems | Circulate coolant through motor components to dissipate heat | Electric vehicles incorporating liquid cooling systems to maintain motor temperature within safe limits |

| Air Cooling Systems | Direct airflow over motor components to remove excess heat | Electric buses utilizing air cooling systems to prevent motor overheating during extended operation |

| Thermal Sensors | Monitor motor temperature and trigger cooling measures as needed | Electric cars equipped with thermal sensors to regulate cooling fan operation based on temperature readings |

2. Overload Protection Systems: Preventing Motor Stress

To prevent mechanical stress and damage, electric motors are equipped with overload protection systems. These systems monitor motor load and torque levels, automatically adjusting power delivery to prevent overload conditions. In EVs, overload protection systems ensure reliable operation under varying driving conditions, enhancing system durability.

Think about carrying a heavy backpack to school. If it’s too heavy, it might hurt your back, right? Electric motors have smart sensors that help them know when they’re carrying too much weight. When they feel too heavy, they ask for a little break, so they don’t get hurt. It’s like having a smart friend who knows when to stop and take a rest!

3. Vibration Damping Mechanisms

Vibration can be detrimental to electric motors, leading to mechanical wear, noise, and reduced lifespan. Excessive vibrations can compromise motor performance and reliability. Electric motors utilize vibration damping mechanisms, such as dynamic balancing and vibration-absorbing materials, to reduce mechanical stress and ensure smooth operation.

For instance, electric vehicles employ vibration damping mounts to isolate the motor from road-induced vibrations, enhancing ride comfort and longevity. Implementing vibration damping mechanisms, such as rubber mounts or advanced suspension systems, can mitigate these effects and promote smoother, more reliable motor operation

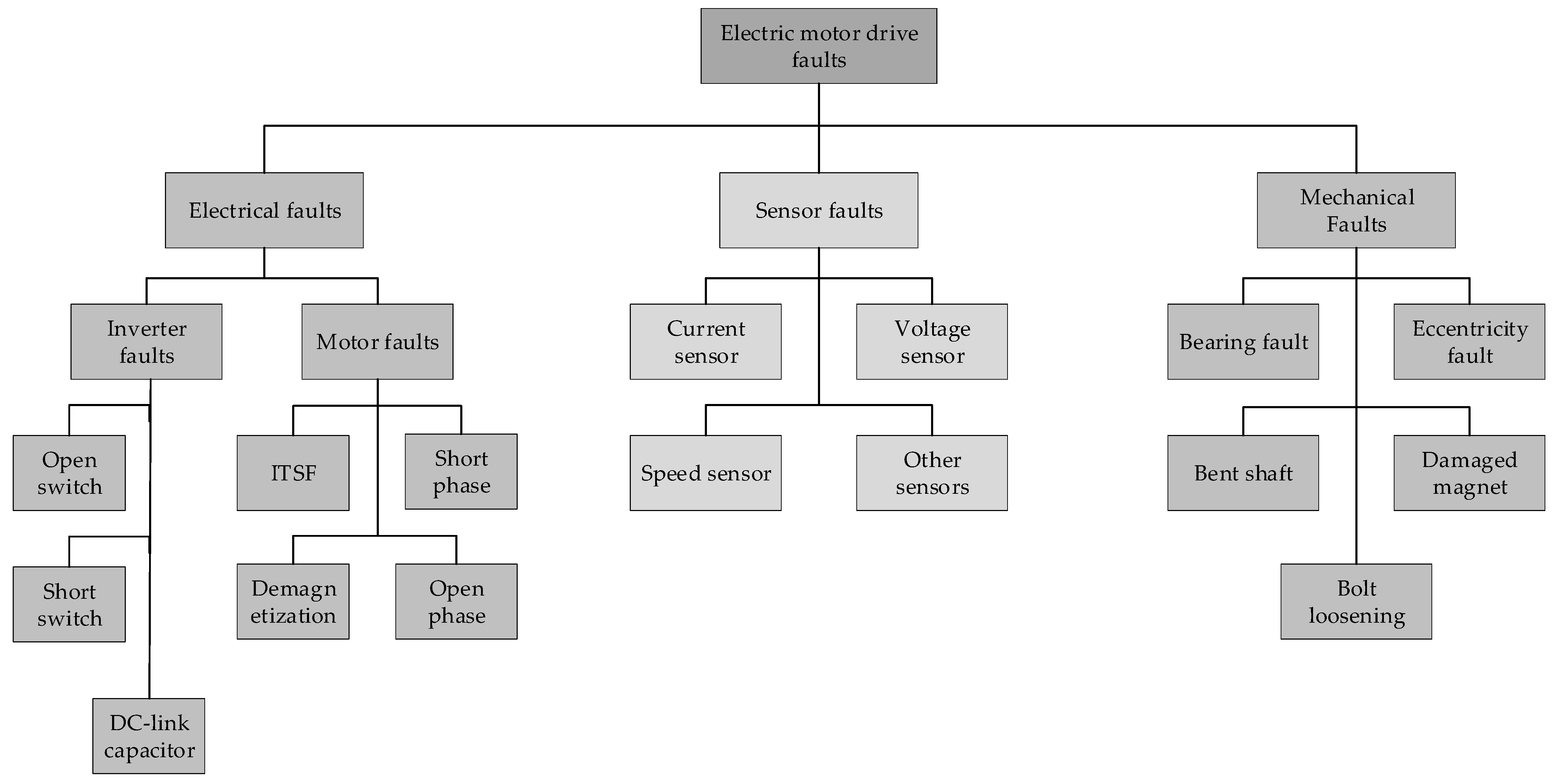

4. Fault Detection and Diagnostics

Modern electric motors feature advanced fault detection and diagnostics capabilities to identify potential stressors and malfunctions. By analyzing motor performance metrics and sensor data, these systems detect abnormalities and trigger protective actions, such as reducing power output or activating safety protocols. For example, electric vehicles utilize onboard diagnostics systems to alert drivers to potential motor issues, enabling timely maintenance and repairs.

Conclusion:

Protective measures for electric motors are not just about preventing failure; they’re about enhancing performance, reliability, and the overall lifespan of these critical components. By prioritizing thermal management, overload protection, vibration damping, and fault detection, we can ensure that electric motors continue to power our vehicles efficiently and effectively for years to come.

Further Reading and Resources:

For those interested in delving deeper into electric motor protection and maintenance, here are some recommended resources:

- IEEE Xplore for research articles on electric motor thermal management and fault detection.

- SAE International for standards and publications on electric vehicle motor design and safety.

References:

- Zhang, S. (2019). Electric Vehicle Machines and Drives: Design, Analysis and Application. Wiley-IEEE Press.

- Miller, J. M. (Ed.). (2020). Electric Motor Control: Theory, Applications, and Design. Pearson.