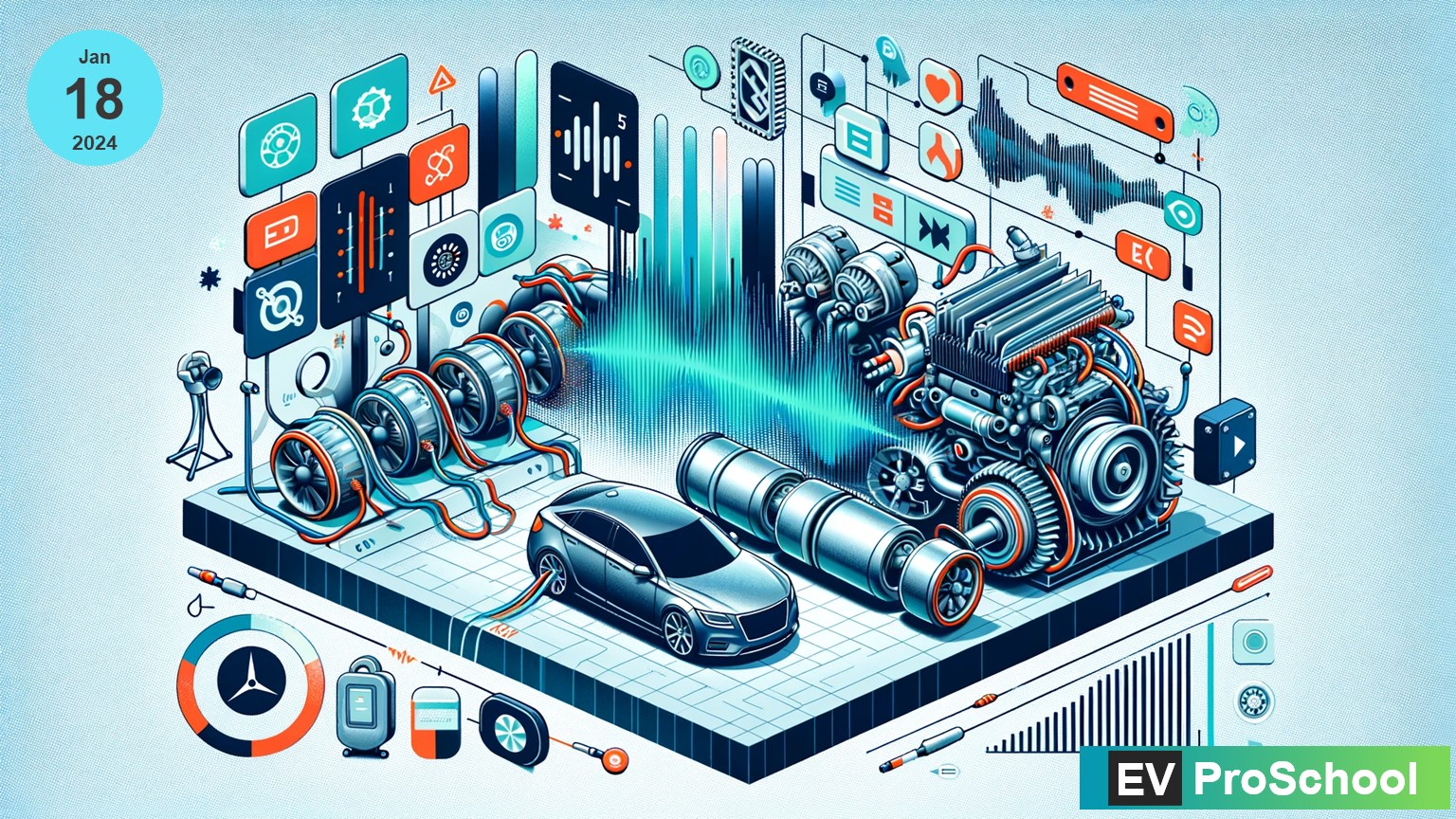

Noise, Vibration, and Harshness (NVH) are critical factors in the automotive industry that significantly impact vehicle comfort and performance. NVH measurements and regulations play a crucial role in ensuring that vehicles meet acceptable noise and vibration levels. In this beginner’s guide, we’ll explore the fundamentals of NVH, its importance in electric vehicles, the process of NVH measurement in India, and the consequences of neglecting NVH checks.

NVH Measurements: An Overview

NVH refers to the study and analysis of noise, vibrations, and harshness experienced by a vehicle’s occupants and its impact on overall vehicle performance. NVH measurements involve assessing noise levels, analyzing vibrations, and evaluating harshness factors to identify potential sources of discomfort and design flaws.

The Importance of NVH in Electric Vehicles (EVs)

NVH is particularly crucial for electric vehicles due to their unique propulsion systems. Unlike internal combustion engines, electric motors operate quietly, making noise from other sources more noticeable. Additionally, electric vehicles lack the engine’s masking effect on vibrations, making NVH control vital to provide a pleasant driving experience for EV users.

NVH Measurement Process in India

In India, NVH measurements are typically performed in specialized testing facilities equipped with advanced instruments. The NVH measurement process involves the following steps:

- Data Collection: Sensors are placed at various points on the vehicle to capture noise and vibration data during different driving conditions.

- Analysis: Collected data is then analyzed using sophisticated software to determine noise frequency, intensity, and vibration patterns.

- Comparative Study: The measured NVH values are compared against established standards and regulations to assess compliance.

- Refinement and Optimization: Based on the analysis, necessary adjustments are made to optimize the vehicle’s NVH characteristics.

- Revalidation: After refinement, the vehicle undergoes revalidation to ensure it meets the required NVH standards.

Consequences of Neglecting NVH Checks

Neglecting NVH measurements can lead to several negative consequences for both manufacturers and consumers:

- Reduced Comfort: Vehicles with high levels of NVH can result in discomfort for occupants, leading to a less enjoyable driving experience.

- Product Reputation: Poor NVH performance can tarnish a vehicle’s reputation and affect customer satisfaction.

- Safety Concerns: NVH issues might indicate underlying structural or mechanical problems that could compromise vehicle safety.

- Regulatory Non-Compliance: Failure to meet NVH regulations can result in legal and financial penalties for manufacturers.

Right NVH balance in EVs

Electric vehicles (EVs) bring new NVH (Noise, Vibration, and Harshness) challenges despite their quieter nature. While the absence of engine noise is a benefit, it reveals other sounds that need addressing for a smoother, quieter ride. Managing vibrations from electric motors is essential for maintaining comfort, and the vehicle’s response to these vibrations—its “harshness”—directly impacts user experience. As we move toward an electric future, achieving the right NVH balance is key to ensuring silence, comfort, and performance. How can we tackle these challenges in EVs? What solutions have you found effective?

NVH Levels as per Government Regulations

The NVH levels for vehicles are typically regulated by government authorities to ensure vehicles meet specific noise and vibration standards. These regulations vary by region and vehicle type, and they are periodically updated to address advancements in technology and environmental concerns.

Contribution of NVH of Electric Vehicles

Source Path Contribution (SPC), also known as Transfer Path Analysis (TPA), is an advanced engineering tool used to quantify the flow of sound and vibration energy from the powertrain to the vehicle’s occupants. In electric vehicles (EVs), SPC helps identify whether the motor is the source of the issue or if the vehicle body is overly sensitive. It enables detailed analysis of sound and vibration transmission, distinguishing between airborne vs. structure-borne noise and radiated noise vs. torque ripple. SPC also allows for vehicle simulations, facilitating “What If?” scenarios like virtual powertrain swaps, enhancing design and performance optimization.

Conclusion: The Quest for Silent and Smooth Mobility

NVH measurements and regulations play a crucial role in enhancing vehicle comfort, safety, and performance. In the context of electric vehicles, where the absence of engine noise is prominent, managing NVH becomes even more critical. Conducting NVH measurements during vehicle development ensures that electric vehicles offer silent and smooth mobility, paving the way for a greener and more enjoyable driving future.

Note: NVH testing and compliance involve technical expertise and specialized equipment. Automotive manufacturers in India usually collaborate with NVH testing service providers and research institutes to achieve optimal NVH performance in their vehicles.