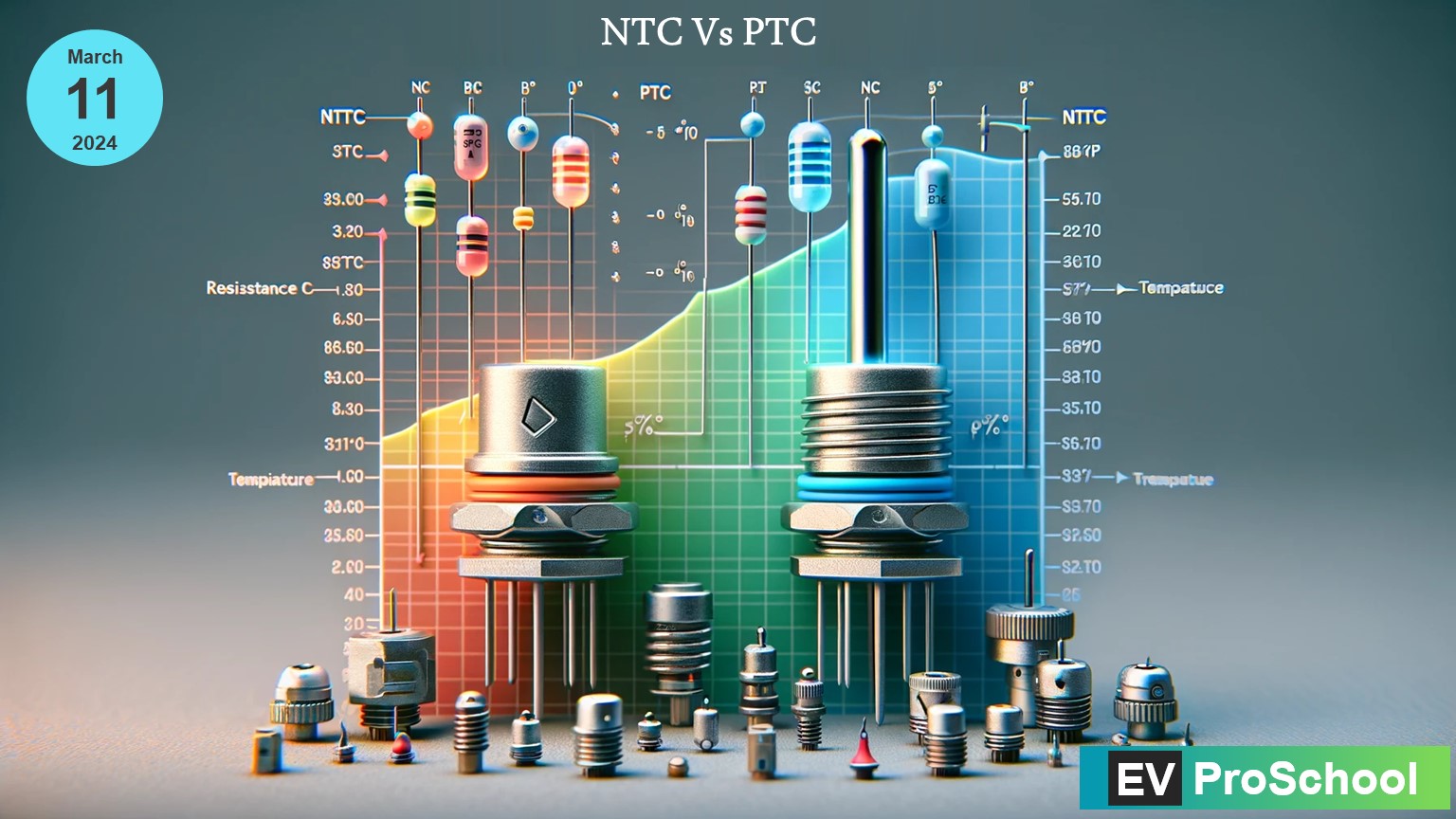

NTC (Negative Temperature Coefficient) Thermistors:

NTC thermistors decrease in resistance as the temperature increases. They are made from semiconductor materials that exhibit a large change in resistance per degree of temperature change. This characteristic makes NTC thermistors highly sensitive to temperature changes and ideal for measuring small variations in temperature.

PTC (Positive Temperature Coefficient) Thermistors:

PTC thermistors, on the other hand, increase in resistance as the temperature increases. They are often made from polycrystalline ceramic materials that exhibit a sharp increase in resistance at a certain threshold temperature. PTCs are commonly used as self-regulating heating elements and for overcurrent protection.

Main Differences and Applications

The main difference between NTC and PTC thermistors lies in their response to temperature changes. NTC thermistors are used for temperature measurement and control because of their precise and predictable resistance-temperature relationship. PTC thermistors are often used for protection purposes, such as limiting inrush currents in power supplies and preventing overheating in electric motors.

Tabular Comparison: NTC vs. PTC Thermistors

| Feature | NTC Thermistors | PTC Thermistors |

|---|---|---|

| Temperature Coefficient | Negative | Positive |

| Resistance Change | Decreases with increasing temperature | Increases with increasing temperature |

| Sensitivity | High sensitivity to temperature changes | Less sensitive than NTCs |

| Applications | Temperature sensing and monitoring, temperature compensation | Overcurrent protection, self-regulating heating elements |

| Advantages | High accuracy, fast response, suitable for a wide temperature range | Simple circuitry, self-regulating, reliable overcurrent protection |

| Disadvantages | Non-linear resistance-temperature relationship, requires calibration | Limited temperature measurement applications, less precise |

Use in the Automotive Industry

Both NTC and PTC thermistors find applications in the automotive industry. NTC thermistors are commonly used for measuring engine coolant temperature, oil temperature, and cabin temperature, providing inputs for the engine control unit (ECU) to optimize performance and efficiency. PTC thermistors are used in applications requiring overcurrent protection, such as in electric motors and power supplies, and as heating elements in automotive cabin heaters.

Conclusion

Choosing between NTC and PTC thermistors depends on the specific requirements of the application. NTC thermistors are preferred for precise temperature measurement and control tasks, while PTC thermistors are chosen for their protective qualities and self-regulating capabilities. In the automotive industry, both types of thermistors play critical roles in ensuring the safety, comfort, and efficiency of vehicles, highlighting their importance in modern automotive design and engineering.