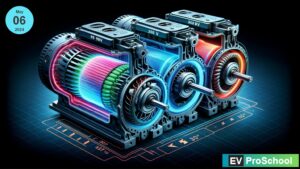

With over three and a half decades in the field of electrical engineering, particularly focusing on motor design and optimization, we have witnessed firsthand the evolution of technologies aimed at enhancing efficiency and performance. One persistent challenge that stands as a testament to the intricacies of electrical engineering is the management of eddy current losses. These losses, inherent in the operation of electrical machines, can significantly impact efficiency and heat management. Drawing from my extensive experience, I aim to share practical insights and strategies to minimize eddy current losses, a task that remains as relevant today as it was at the start of my career.

Understanding Eddy Currents

Eddy currents are loops of electrical current induced within conductors by a changing magnetic field in the conductor, according to Faraday’s law of electromagnetic induction. While essential to the functioning of many electrical devices, they can also lead to undesirable heat generation and energy loss, particularly in the cores of transformers and the rotors of electric motors.

The Source of Eddy Currents

Eddy currents arise when a conductor experiences a change in the magnetic field, leading to the generation of circular currents within the conductor itself. These currents face resistance within the conductor, and as a result, their energy is dissipated in the form of heat. In the context of electric motors and transformers, this phenomenon is a double-edged sword, contributing to the device’s function while also imposing efficiency penalties.

Strategies for Minimizing Eddy Current Losses

Over the years, I’ve applied and refined multiple strategies to mitigate eddy current losses. Here are the most effective ones:

Lamination of Core Materials

One of the earliest lessons I learned in my career was the significant impact of core lamination. By constructing the core of transformers and motors from thin, insulated layers of steel, we can drastically reduce the pathway available for eddy currents, thereby minimizing their intensity and the associated losses. The thinner these laminations, the lower the eddy current losses, though practical limitations and manufacturing considerations always play a role in determining the optimal thickness.

Use of High-Resistivity Materials

Another approach is selecting materials with high electrical resistivity for constructing the core. Higher resistivity means that any induced eddy currents will encounter more resistance, reducing their intensity and the resulting heat generation. Materials such as silicon steel, amorphous steel, and ferrites have been game-changers in this regard, offering an effective balance between magnetic permeability and resistivity.

Optimization of Magnetic Flux Paths

Designing magnetic circuits to ensure that flux paths are as short and direct as possible can also reduce the generation of eddy currents. This involves not just the physical layout of the core but also the strategic placement of windings and the use of magnetic shunts or gaps to guide the magnetic field efficiently through the core.

Frequency Considerations

The frequency of the magnetic field change directly influences eddy current losses, with higher frequencies leading to greater losses. In applications where frequency can be controlled or modified, optimizing this parameter can yield significant efficiency improvements. For variable-frequency drives and other adjustable-speed applications, this insight has been crucial in reducing losses.

Personal Reflections

Reflecting on the progression of my career, it’s evident that the battle against eddy current losses is won through a combination of materials science, electrical theory, and practical engineering. Each project has been a learning opportunity, pushing me to innovate and apply both time-tested and novel strategies to overcome efficiency challenges.

Looking Ahead

As we stand on the brink of new technological revolutions, with the advent of wide-bandgap semiconductors and advances in nanotechnology, the future holds even more promise for the reduction of eddy current losses. These developments, coupled with a deeper understanding of electromagnetic phenomena, pave the way for more efficient, robust, and compact electrical machines.

Conclusion

The journey to minimize eddy current losses is a vivid illustration of the broader engineering challenge: optimizing performance while navigating the constraints of physical laws and material properties. The strategies outlined here, borne of decades of hands-on experience and theoretical exploration, represent just a fraction of the engineering toolkit. As we continue to innovate and refine our approaches, the pursuit of efficiency remains a driving force behind the evolution of electrical engineering, promising a future where energy losses are ever diminished, and the potential of our technologies is fully realized.