Detailed Blog Post Strategy: “Life Cycle Assessment of Electric 2W & 3W Batteries”

This blog post will analyze the entire lifecycle of electric two-wheeler (2W) and three-wheeler (3W) batteries, covering production, usage, and recycling phases, with a focus on their environmental impact and carbon footprint. The post will incorporate India-specific insights, explore global trends, and offer actionable recommendations for reducing battery-related emissions.

1. Objectives

Purpose:

• To educate readers about the environmental impact of EV batteries from produc tion to recycling.

• Highlight the carbon footprint at each stage and discuss strategies for minimizing emissions.

• Provide global trends and innovations for sustainable battery lifecycle management.

2. Target Audience

• EV owners and enthusiasts interested in the environmental aspects of battery production and disposal.

• Policymakers and sustainability advocates exploring ways to make EVs more eco-friendly.

• Industry professionals and startups seeking insights into sustainable battery practices.

3. Blog Outline

Title Options:

• Main Title: Life Cycle Assessment of Electric 2W & 3W Batteries

• SEO-Friendly Title: Environmental Impact of EV Batteries: From Production to Recycling

Introduction: Understanding the Journey of an EV Battery

• Hook:

“Did you know that the journey of an EV battery—from mining raw materials to recycling—determines its true environmental impact?”

• Introduce the concept of life cycle assessment (LCA):

• A comprehensive analysis of the environmental impact of a product at every stage.

• Preview the blog: “In this post, we’ll analyze the lifecycle of 2W and 3W EV batteries, from production to recycling, and explore their carbon footprint and sustainability solutions.”

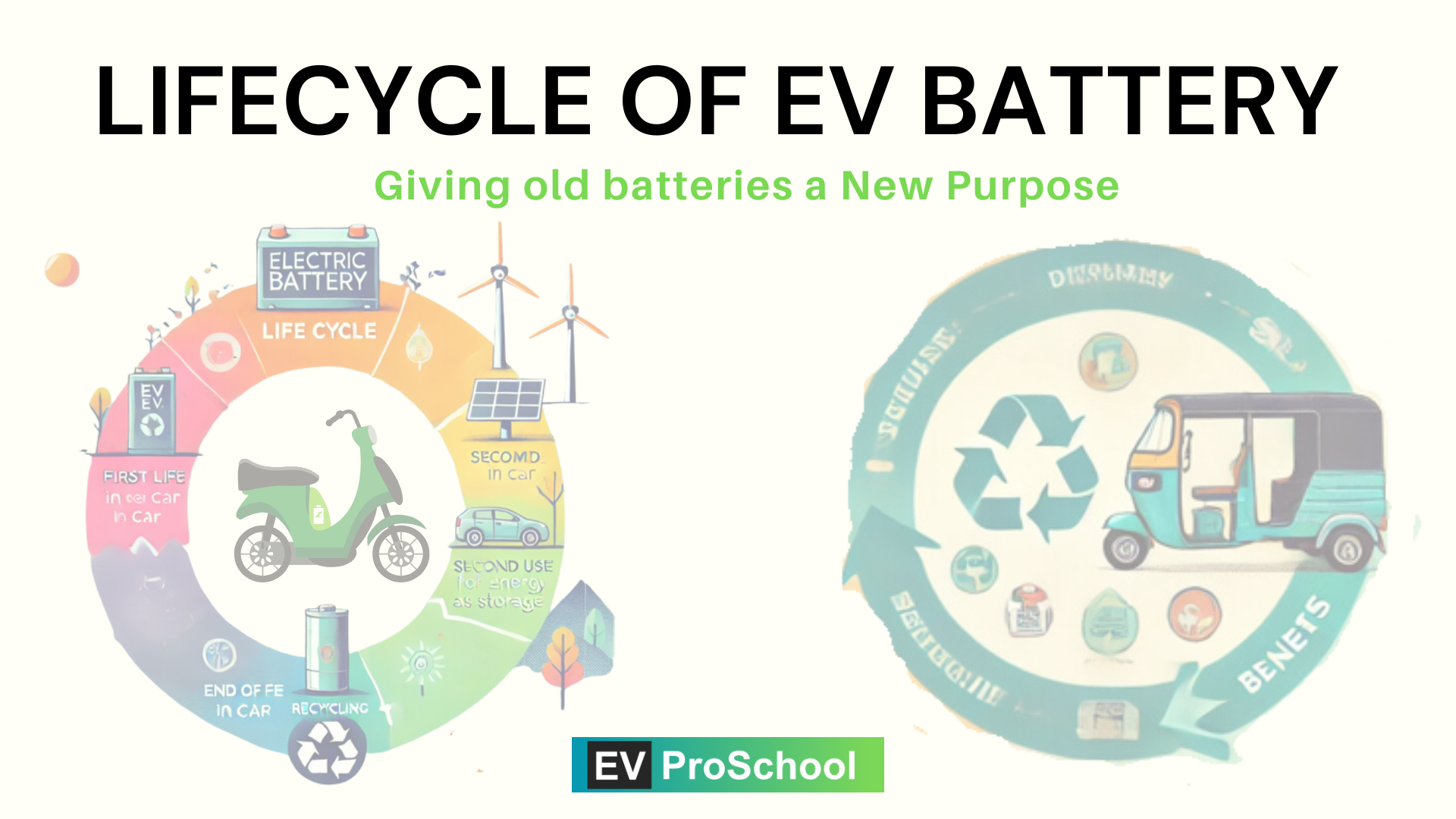

Section 1: The Lifecycle of an EV Battery

1. Production Phase

• Raw Material Extraction:

• Mining of lithium, cobalt, nickel, and manganese.

• Environmental concerns: High water consumption, habitat destruction, and pollution.

• Manufacturing Process:

• High energy consumption during battery cell production.

• Example: Manufacturing a lithium-ion battery can emit ~70–110 kg CO2 per kWh of capacity.

2. Usage Phase

• Efficiency During Operation:

• EV batteries reduce tailpipe emissions to zero.

• For Indian 2Ws and 3Ws, EVs can offset their production emissions in 1–2 years of usage compared to ICE vehicles.

• Battery Degradation:

• Gradual capacity loss over time, affecting energy efficiency.

3. End-of-Life Phase

• Recycling:

• Recovery of valuable materials like lithium, cobalt, and nickel.

• Reduces the need for raw material extraction.

• Reuse:

• Batteries repurposed for second-life applications, such as energy storage systems.

Section 2: Environmental Impact at Each Stage

1. Carbon Footprint of Production

• Mining and processing raw materials account for ~40% of the battery’s total lifecycle emissions.

• Example: Mining 1 ton of lithium requires ~500,000 gallons of water, impacting local ecosystems.

2. Carbon Offset During Usage

• EVs powered by renewable energy have a significantly lower carbon footprint compared to those charged using coal-based electricity.

• Stat: Indian 2Ws and 3Ws using grid electricity still emit ~50% less CO2 than ICE vehicles.

3. Challenges at End-of-Life

• Improper Disposal: Leads to environmental contamination.

• Energy-Intensive Recycling: Recycling processes like pyrometallurgy and hydrometallurgy emit CO2.

Section 3: Global Trends in Sustainable Battery Lifecycles

1. Transition to Cobalt-Free Batteries

• Reduces reliance on environmentally damaging cobalt mining.

• Example: LFP (Lithium Iron Phosphate) batteries are gaining popularity for 2Ws and 3Ws.

2. Renewable Energy-Powered Manufacturing

• Companies like Tesla and CATL are building gigafactories powered by solar and wind energy.

3. AI in Battery Recycling

• AI-driven sorting technologies improve material recovery rates and reduce emissions during recycling.

4. Closed-Loop Systems

• Manufacturers like Umicore and Lohum Cleantech are creating closed-loop supply chains to reuse materials from old batteries.

Section 4: India-Specific Insights

1. Rising EV Adoption

• India’s two- and three-wheeler market is rapidly electrifying, with over 50% of new sales in 2W expected to be electric by 2030.

2. Challenges in Recycling Infrastructure

• Limited number of battery recycling plants in India.

• Informal recycling practices can lead to pollution and material wastage.

3. Government Policies

• FAME II subsidies incentivize sustainable EV adoption.

• India’s Battery Waste Management Rules 2022 mandate proper disposal and recycling.

4. Local Innovations

• Sun Mobility: Battery swapping stations that promote efficient reuse.

• Tata Chemicals: Building India’s battery recycling ecosystem.

Section 5: Solutions for a Greener Battery Lifecycle

1. Use of Renewable Energy in Charging and Manufacturing

• Powering 2Ws and 3Ws with solar energy can reduce lifecycle emissions by up to 40%.

2. Consumer Awareness

• Educating EV users about proper charging practices and recycling options.

3. Investment in Recycling Infrastructure

• Scaling up recycling facilities in India to handle the expected surge in battery waste.

4. Second-Life Applications

• Promoting the use of retired EV batteries for rural electrification and backup power.

Conclusion: Building a Sustainable Future for EVs

• Recap the importance of analyzing the lifecycle of EV batteries to understand their true environmental impact.

• Emphasize the role of innovations, government policies, and consumer awareness in minimizing the carbon footprint of 2W and 3W batteries.

• End with a call-to-action:

“Together, we can make EVs not just a solution for cleaner transport, but a cornerstone of a sustainable future.”

4. Writing Style and Tone

• Tone: Educational yet optimistic, emphasizing solutions and innovations.

• Use analogies to simplify technical concepts:

• “Think of an EV battery as a marathon runner—it needs the right training (production), performance (usage), and recovery (recycling) to excel.”

5. Suggested Visuals and Graphics

1. Lifecycle Diagram: From production to recycling, showing emissions at each stage.

2. Infographic: Carbon footprint comparison of EV batteries and ICE engines.

3. Global Trends Map: Highlighting countries and companies leading in sustainable battery practices.

4. Bar Chart: Environmental benefits of battery reuse vs recycling.

6. SEO Optimization Strategy

Focus Keyword:

“Lifecycle assessment of EV batteries”

Supporting Keywords:

• Environmental impact of EV batteries

• Carbon footprint of 2W and 3W batteries

• Sustainable EV battery recycling

• Life cycle analysis for electric vehicle batteries

Meta Description:

“Analyze the lifecycle of electric two-wheeler and three-wheeler batteries, from production to recycling. Discover their environmental impact, carbon footprint, and global trends in sustainability.”

Alt Text for Feature Image:

“Diagram showing the lifecycle of EV batteries, from production to recycling, and their environmental impact.”

7. Blog Length and Target Audience

• Word Count: 2,000–2,400 words to provide a detailed analysis.

• Target Audience: EV users, sustainability advocates, policymakers, and industry professionals.

This strategy provides a comprehensive and actionable perspective on the lifecycle of 2W and 3W EV batteries, tailored to India’s context and global trends in sustainability.