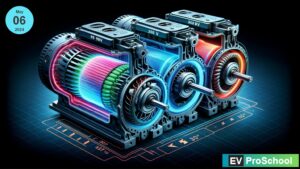

Electric motors are the heartbeat of electric vehicles (EVs), converting electrical energy from the battery into mechanical energy that drives the wheels. Unlike traditional internal combustion engines, electric motors are quieter, have fewer moving parts, and deliver instant torque, resulting in a smooth and responsive driving experience. This post will explore the primary types of electric motors used in EVs, their efficiency and torque characteristics, and the various motor placement options that manufacturers use to optimize performance.

1. Types of Electric Motors in EVs

The type of motor selected for an EV depends on various factors, including cost, efficiency, and the specific driving characteristics desired. Here are the most common types of motors used in electric vehicles:

- Induction Motors (IM):

Induction motors, also known as asynchronous motors, were popularized in EVs by Tesla. They operate by generating a magnetic field in the rotor without direct electrical connection, using electromagnetic induction. This design enables a simple, rugged motor that’s easy to cool and capable of handling high speeds. However, induction motors are slightly less efficient than other motor types at lower speeds, making them better suited for applications where high performance is prioritized. - Permanent Magnet Synchronous Motors (PMSM):

PMSMs use permanent magnets embedded in the rotor, creating a strong magnetic field that allows for high torque and efficiency. This motor type is compact, lightweight, and provides high efficiency at both low and high speeds, making it ideal for passenger EVs where maximizing range and energy efficiency is essential. However, the cost of rare-earth magnets used in PMSMs can be high, influencing the overall price of the vehicle. - Brushless DC Motors (BLDC):

BLDC motors are similar in design to PMSMs, with permanent magnets on the rotor. They operate using direct current and an electronic controller that switches the current to different windings, providing torque. BLDC motors are known for their high power density, efficiency, and smooth performance. However, their complex control systems can make them more expensive to manufacture, making them less common in mass-market EVs compared to PMSMs. - Switched Reluctance Motors (SRM):

SRMs operate by switching magnetic fields in the stator, creating magnetic reluctance torque that turns the rotor. This motor type has no magnets and a simple design, making it cost-effective and durable. However, it can produce noise and vibrations, which is why it’s less common in EVs that prioritize a smooth, quiet ride. SRMs are used primarily in applications where cost and robustness are prioritized over refinement.

2. Motor Efficiency and Torque Characteristics

Electric motors are celebrated for their high efficiency and ability to produce peak torque from a standstill, unlike ICE engines, which need to reach certain RPMs to deliver peak torque. Here’s a closer look at the efficiency and torque characteristics of different motor types:

- Instant Torque Delivery:

All electric motors in EVs provide instant torque, allowing for quick acceleration and responsiveness. This is particularly beneficial for city driving, where frequent starts and stops are common. It also contributes to the smooth, jerk-free experience that EVs are known for. - Efficiency Across RPM Ranges:

Motor efficiency is crucial for optimizing an EV’s range. PMSMs and BLDC motors are highly efficient across a wide RPM range, making them suitable for vehicles where efficiency is paramount. Induction motors, while efficient at high speeds, tend to be slightly less efficient at lower speeds. EV manufacturers often optimize this trade-off by adjusting motor size and control systems to ensure efficiency at common driving speeds. - Torque Curve:

Electric motors typically provide maximum torque at zero RPM, then gradually decrease as speed increases. This is ideal for city driving but can pose challenges for sustained highway speeds. Some EVs overcome this with sophisticated power electronics that manage torque at varying speeds to provide consistent performance without sacrificing efficiency.

3. Motor Placement in EVs: In-Wheel vs. On-Axle

Motor placement in EVs impacts not only the vehicle’s weight distribution but also its performance, handling, and design flexibility. The two most common placements are in-wheel motors and on-axle motors.

- In-Wheel Motors:

In-wheel motors, as the name implies, are installed directly within the wheel hub, eliminating the need for a central transmission. Each wheel can be independently controlled, providing torque vectoring that improves handling and stability, especially in performance-oriented vehicles. In-wheel motors free up space within the vehicle, allowing for more design freedom and potential for increased passenger or cargo space. However, they also increase unsprung weight, which can negatively impact ride quality. Moreover, since in-wheel motors are directly exposed to road conditions, they require additional durability and robust weather protection. - On-Axle Motors:

On-axle motors are mounted on the axle, where they transmit power to the wheels through a single-speed gearbox or differential. This setup is more commonly used because it offers a balance of performance and durability without compromising ride quality. On-axle motors also simplify motor cooling and allow for smoother handling characteristics. While they don’t offer the same precision of torque vectoring as in-wheel motors, they’re generally more affordable to manufacture and easier to maintain, making them ideal for a broad range of EVs.

4. Advanced Motor Technologies and Future Directions

As the EV market evolves, new advancements in motor technologies are emerging to address challenges related to efficiency, cost, and performance. Some of these innovations include:

- Axial Flux Motors: Unlike traditional radial flux motors, axial flux motors offer a pancake-like design that is both compact and lightweight, making them ideal for maximizing interior space in EVs. These motors also have high torque density, which enhances performance while reducing weight.

- High-Efficiency Cooling Systems: Motor efficiency can be impacted by temperature, and high-efficiency cooling systems are increasingly being developed to improve motor performance, particularly in induction and permanent magnet motors.

- Integration with Power Electronics: By closely integrating the motor with advanced power electronics, EV manufacturers are improving motor control, achieving higher efficiency, and optimizing torque delivery across a broader range of driving conditions.

Conclusion

Electric motors are pivotal to the efficiency, performance, and overall driving experience of electric vehicles. Each motor type offers unique benefits and trade-offs in terms of efficiency, cost, and performance, and motor placement plays a critical role in handling and design. As EV technology advances, we can expect continued innovation in electric motor design, contributing to more powerful, efficient, and accessible electric vehicles. From induction motors to axial flux innovations, the journey of electric motors is just beginning, promising an exciting future for the electric vehicle landscape.