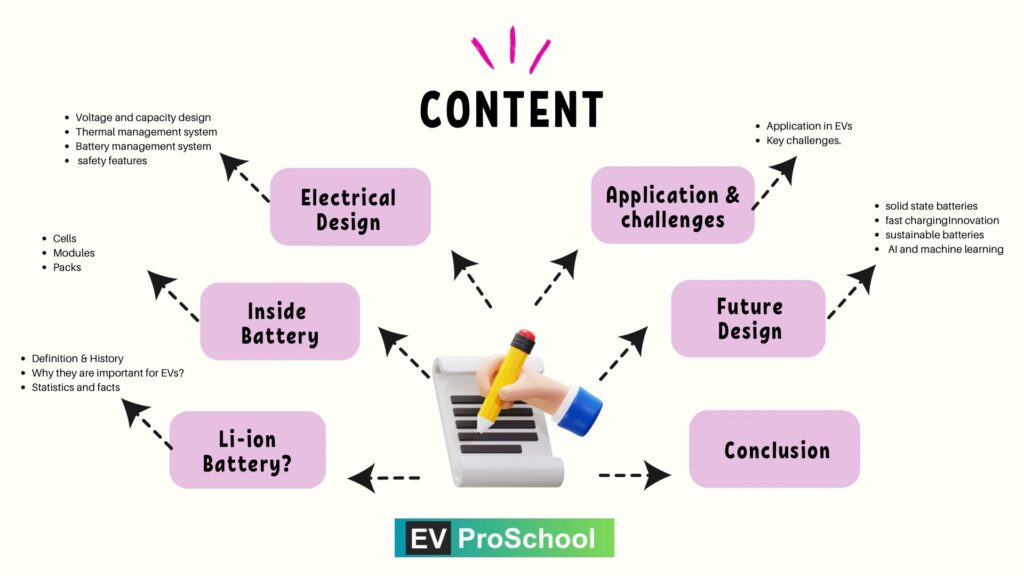

2. Blog Outline

Title Options:

- SEO-Friendly Title: Understanding Lithium-ion Batteries: Packs, Modules, and Design Considerations

Introduction: The Power Behind the EV Revolu

- Hook:

“Lithium-ion batteries are everywhere—from your smartphone to your electric car. But have you ever wondered what makes them so powerful and efficient?” - Introduce the importance of lithium-ion batteries in powering EVs and modern technology.

- Explain what readers will learn: “In this post, we’ll explore the inner structure of Li-ion batteries, break down battery packs and modules, and uncover the critical design considerations that make these batteries the gold standard for EVs.”

Section 1: What Are Lithium-Ion Batteries?

- Definition and History:

- Define lithium-ion batteries as rechargeable energy storage devices using lithium-based chemistry.

- Brief history: Developed in the 1970s and commercialized by Sony in 1991.

- Why They’re Important for EVs:

- High energy density for longer range.

- Lightweight design for better efficiency.

- Ability to handle multiple charge-discharge cycles.

- Stat/Fact to Include:

“By 2030, lithium-ion batteries are expected to power over 90% of electric vehicles worldwide.”

Section 2: Inside the Lithium-Ion Battery: Packs, Modules, and Cells

1. Battery Cells:

- What They Are:

- The smallest unit where chemical reactions store and release energy.

- Types: Cylindrical (e.g., 18650, 4680), Prismatic, and Pouch.

- Energy Density vs. Power Density:

- Energy density determines range; power density impacts acceleration.

2. Battery Modules:

- What They Are:

- Groups of cells connected in series/parallel for scalability.

- Include structural support, wiring, and basic thermal management.

- Why Modules Matter:

- Allow easier maintenance and fault isolation.

- Modular design simplifies assembly for EV manufacturers.

3. Battery Packs:

- What They Are:

- The final assembly of modules housed in a protective casing.

- Incorporates cooling systems, Battery Management Systems (BMS), and fire barriers.

- Key Role in EVs:

- Packs integrate all safety features and ensure consistent performance.

- Visual Idea: Exploded view of a lithium-ion battery pack showing cells, modules, and the outer casing.

Section 3: Electrical Design Considerations in Lithium-Ion Batteries

1. Voltage and Capacity Design:

- Voltage: Determined by cells connected in series. Higher voltage improves power output.

- Capacity: Determined by cells connected in parallel. Higher capacity extends range.

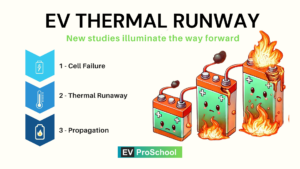

2. Thermal Management Systems:

- Why It’s Critical:

- Prevents overheating (thermal runaway).

- Ensures efficiency in extreme temperatures.

- Technologies Used:

- Liquid cooling (e.g., Tesla).

- Air cooling (used in budget EVs).

3. Battery Management Systems (BMS):

- What It Does:

- Monitors voltage, temperature, and charge levels across all cells.

- Ensures safe charging and discharging to avoid damage.

4. Safety Features:

- Fireproof Barriers: Isolate cells to prevent fire spread.

- Pressure Release Valves: Protect against gas buildup.

- Smart Sensors: Detect anomalies in real-time.

Section 4: Real-World Applications and Challenges

1. Applications in EVs:

- Popular Models Using Li-ion Batteries:

- Tesla (4680 cells).

- Nissan Leaf (prismatic cells).

- Hyundai Kona Electric (pouch cells).

2. Key Challenges:

- Raw Material Sourcing:

- Lithium and cobalt shortages.

- Environmental impact of mining.

- Battery Recycling:

- Need for closed-loop systems to recover lithium and other materials.

- Durability vs Cost:

- Balancing affordability with longer lifespans.

Section 5: Future of Lithium-Ion Battery Design

1. Solid-State Batteries:

- How solid-state technology could replace liquid electrolytes for higher safety and energy density.

2. Fast Charging Innovations:

- New materials (like silicon anodes) enabling ultra-fast charging without degrading cells.

3. Sustainable Batteries:

- Cobalt-free batteries to reduce dependency on scarce resources.

- Use of recycled materials in new batteries.

4. AI and Machine Learning:

- AI-driven BMS to optimize battery performance and predict failures.

Conclusion: The Backbone of Electric Mobility

- Recap the importance of lithium-ion batteries in powering the EV revolution.

- Highlight how advancements in packs, modules, and design are making EVs more efficient, safe, and sustainable.

- End with a call-to-action:

“Curious about how batteries power your EV? Explore our other guides on battery efficiency and emerging technologies!”

3. Writing Style and Tone

- Tone: Informative but accessible, balancing technical depth with engaging explanations.

- Use relatable analogies:

- “Think of a battery pack as a carefully organized Lego set—each module is a block, and the cells inside are the tiny pieces that hold it all together.”

4. Suggested Visuals and Graphics

- Exploded View Diagram: Lithium-ion battery pack structure (cells, modules, and casing).

- Comparison Table: Energy density and applications of cylindrical, prismatic, and pouch cells.

- Infographic: How voltage and capacity are determined in a battery system.

- Future Trends Chart: Evolution from lithium-ion to solid-state batteries.

5. SEO Optimization Strategy

Focus Keyword:

“Lithium-ion batteries”

Supporting Keywords:

- Lithium-ion battery packs

- Battery modules in EVs

- Electrical design of lithium-ion batteries

- Thermal management in EV batteries

Meta Description:

“Take a deep dive into lithium-ion batteries! Learn about battery packs, modules, and electrical design considerations that make these batteries the backbone of electric vehicles.”

Alt Text for Feature Image:

“Exploded view of a lithium-ion battery pack showing cells, modules, and thermal management systems.”

6. Blog Length and Target Audience

- Word Count: 2,000–2,500 words to provide an in-depth yet engaging guide.

- Target Audience: EV enthusiasts, engineers, and those curious about the science of EV batteries.

With this strategy, the blog will offer a comprehensive, engaging, and SEO-optimized overview of lithium-ion batteries, their structure, and their role in the EV industry.

Lithium-ion batteries are the driving force behind the electrification revolution, powering everything from smartphones to electric vehicles (EVs). While most people are familiar with everyday AA and AAA cells, understanding the complexities of lithium-ion batteries and why they are crucial for EVs can be a bit of a puzzle. Lets break down the science behind lithium-ion batteries, explore the reasons behind their cost and manufacturing challenges.

The Marvels of Lithium-ion Batteries

Lithium-ion batteries (Li-ion) are a type of rechargeable battery that store energy through a chemical process. Unlike everyday cells, they use lithium ions to shuttle back and forth between the positive and negative electrodes during charging and discharging. This unique process gives lithium-ion batteries a higher energy density and longer lifespan, making them ideal for high-demand applications like EVs.

Cost and Manufacturing Challenges:

The cost and manufacturing complexity of lithium-ion batteries stem from several factors:

- Specialized Components:

Lithium-ion batteries require specialized components, such as lithium cobalt oxide or lithium iron phosphate for the cathode, graphite for the anode, and a conductive electrolyte. These materials are more expensive and harder to source compared to the everyday zinc and manganese dioxide used in AA and AAA cells.

- Precision Manufacturing

Manufacturing lithium-ion batteries requires a high degree of precision and quality control. The assembly process involves intricate steps, ensuring that the electrodes, electrolyte, and separator are correctly aligned to prevent short-circuiting and maximize battery performance. This precision makes the production of lithium-ion batteries more intricate and time-consuming than standard cells.

Mobile Phone Batteries vs. Electric Vehicle Batteries: A Capacity Comparison:

To put the capacity of lithium-ion batteries into perspective, let’s compare it to the batteries we find in our mobile phones. Most smartphones today come equipped with batteries ranging from 3000mAh to 5000mAh. Now, an entry-level electric car may require a battery pack with a capacity of around 40-60 kWh (kilowatt-hours) to achieve a decent driving range.

- The Magnitude Difference:

To visualize the difference, let’s consider a smartphone battery with a capacity of 4000mAh (4Ah). To power an electric car with a 40kWh battery, we would need the equivalent of 10,000 smartphone batteries! This staggering difference showcases the vast scale and complexity of electric vehicle lithium-ion batteries.

EV Lithium-ion Batteries: Pioneering the Green Revolution:

Despite the challenges, the benefits of lithium-ion batteries in electric vehicles are unparalleled. They offer higher energy densities, longer lifespans, faster charging times, and are much cleaner for the environment compared to conventional internal combustion engines. Electric vehicles are leading the green revolution, paving the way for a sustainable and eco-friendly future.

Conclusion: Empowering a Cleaner Tomorrow

As we look to the future, understanding the significance of lithium-ion batteries in the electric vehicle ecosystem is crucial. These advanced powerhouses are reshaping the automotive industry and propelling us towards a greener and cleaner world. While they may be more expensive and difficult to manufacture compared to everyday cells, their exceptional performance and contributions to sustainability make them indispensable for the electric revolution. So, the next time you use your smartphone or marvel at an electric car, remember the extraordinary lithium-ion battery silently powering the world’s journey towards a cleaner tomorrow.