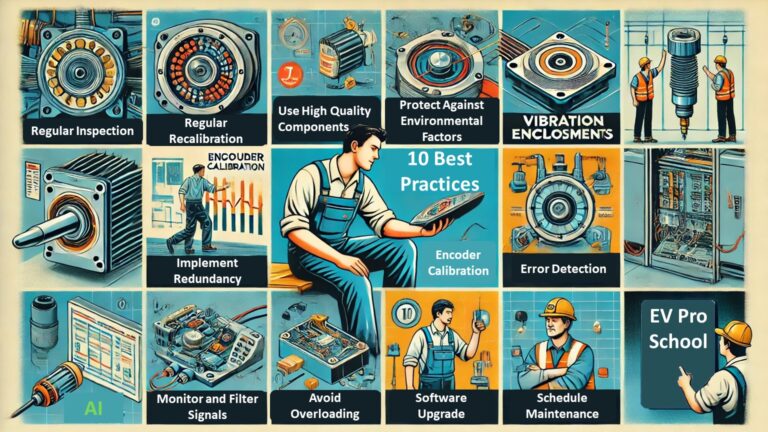

10 Best Practices for Maintaining Encoder Calibration Over Time in IPM Motors

Ensure long-term accuracy in IPM motor encoders with these 10 best practices. Discover essential strategies, from vibration mitigation to software updates, for reliable motor performance in demanding applications